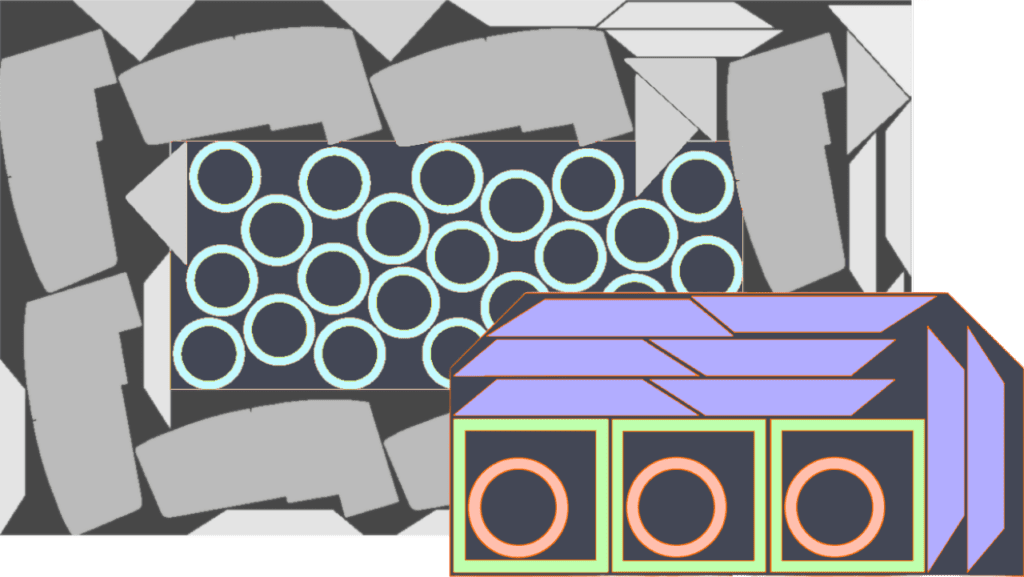

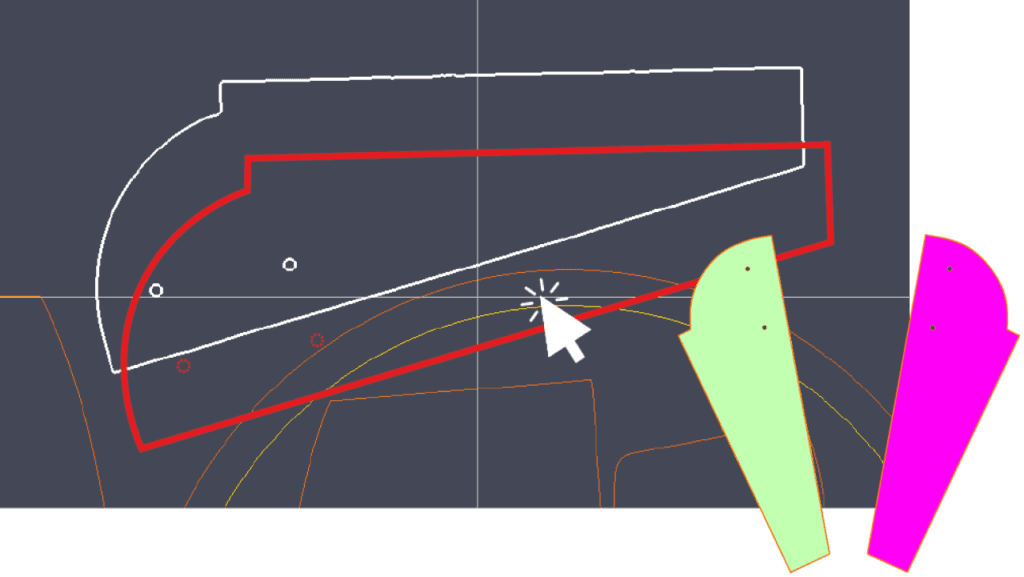

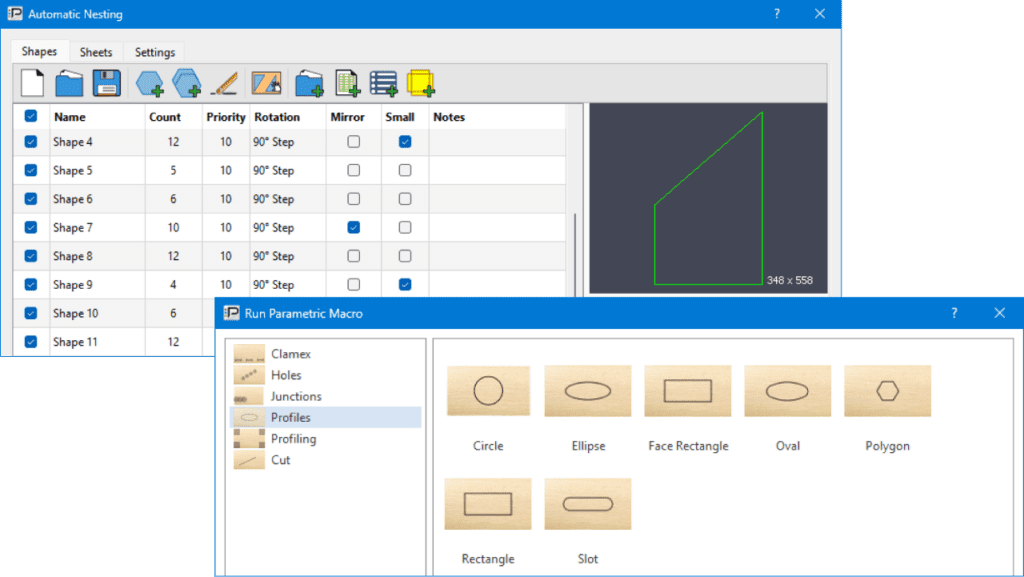

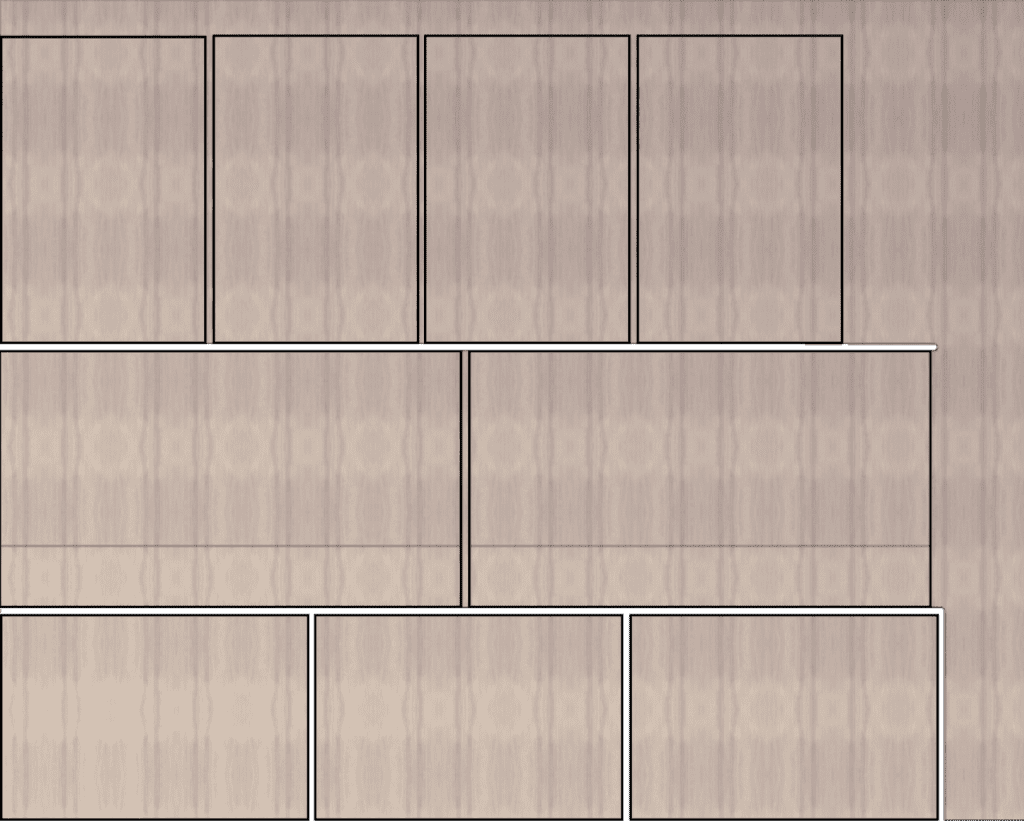

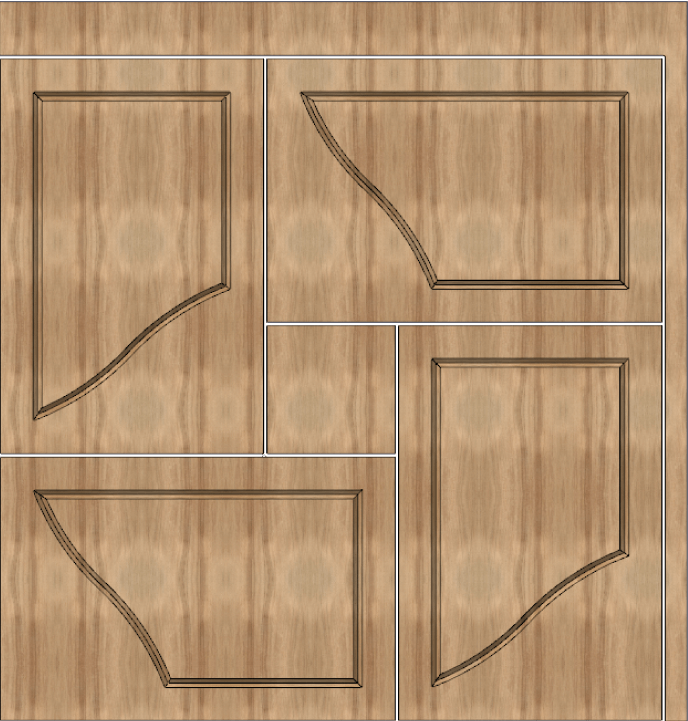

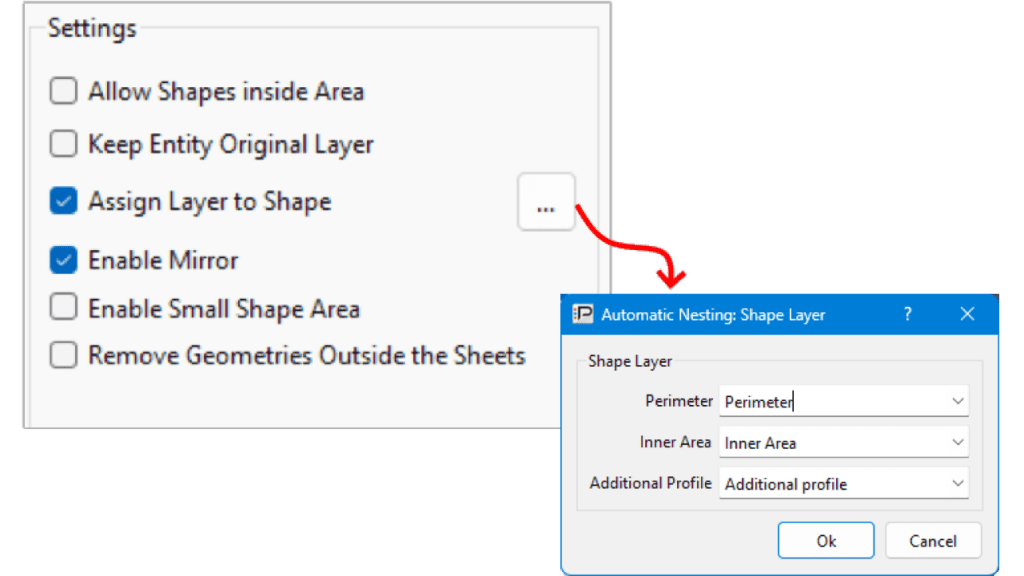

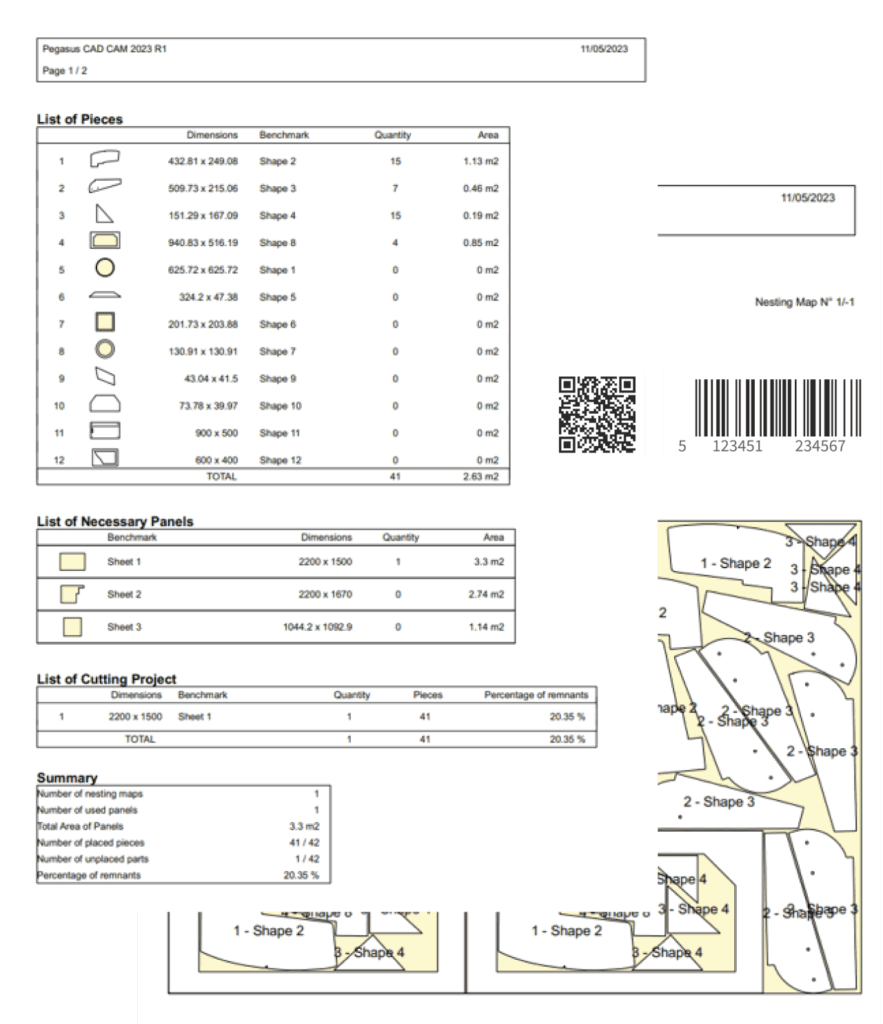

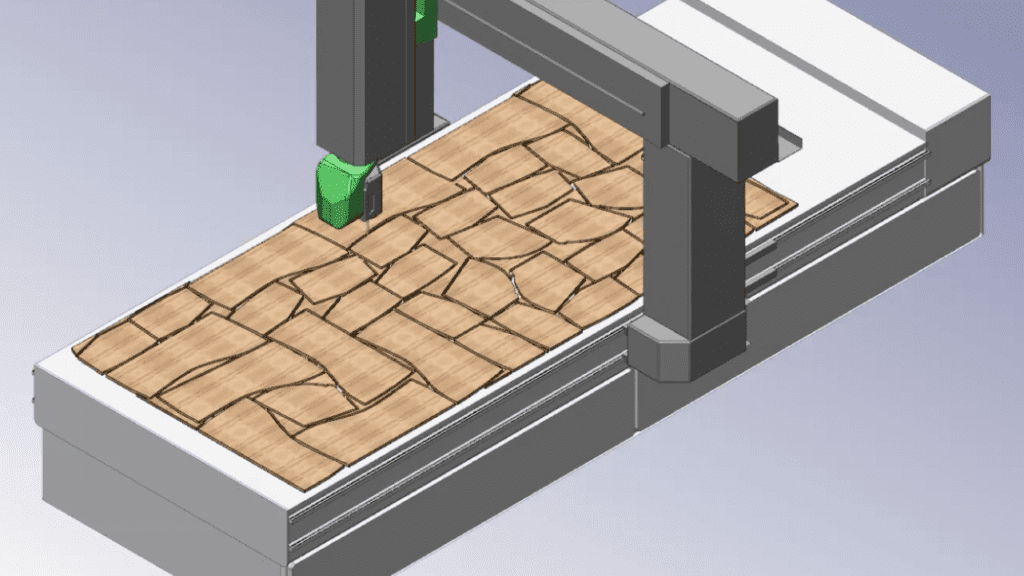

Easy-to-use, high-performance nesting software with one of the best computing engines on the market. It is a complete CAD-CAM software, managing the whole process, from drawing to execution in the CNC machine of choice.

![]() download the brochure

download the brochure

Stay informed, you'll always be one step ahead!

Subscribe to our Newsletter and receive the most important news and exclusive offers.