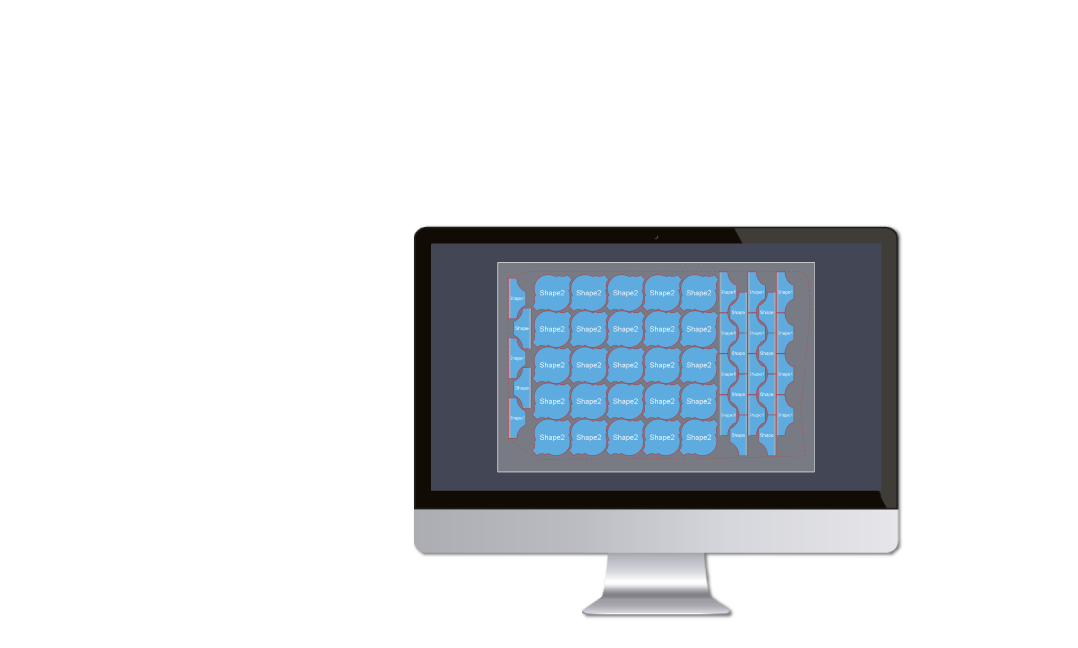

Software versions for stone and marble processing with 3- and 5-axis waterjet machines.

Designed to ensure precision and versatility, it enables vertical edge cutting, constant inclination, or variable angle processing.

Thanks to its simple and intuitive interface, Pegasus Waterjet can be used even without advanced technical skills.

![]() download the brochure

download the brochure