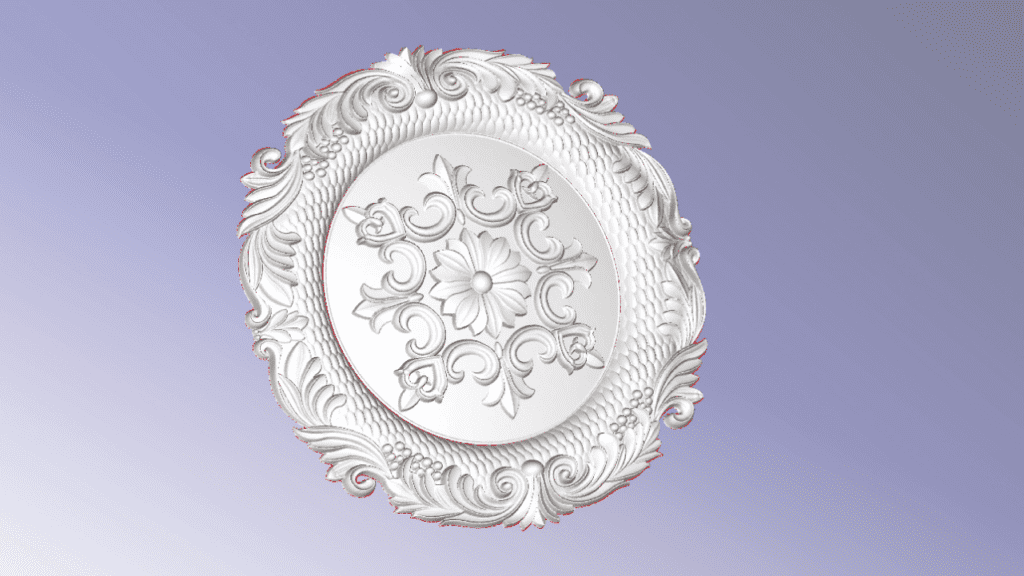

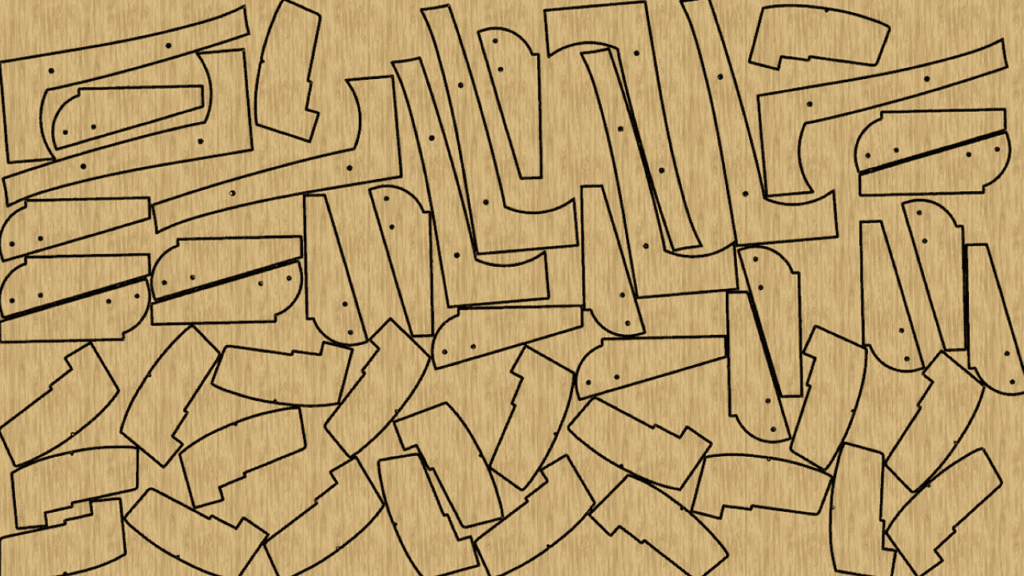

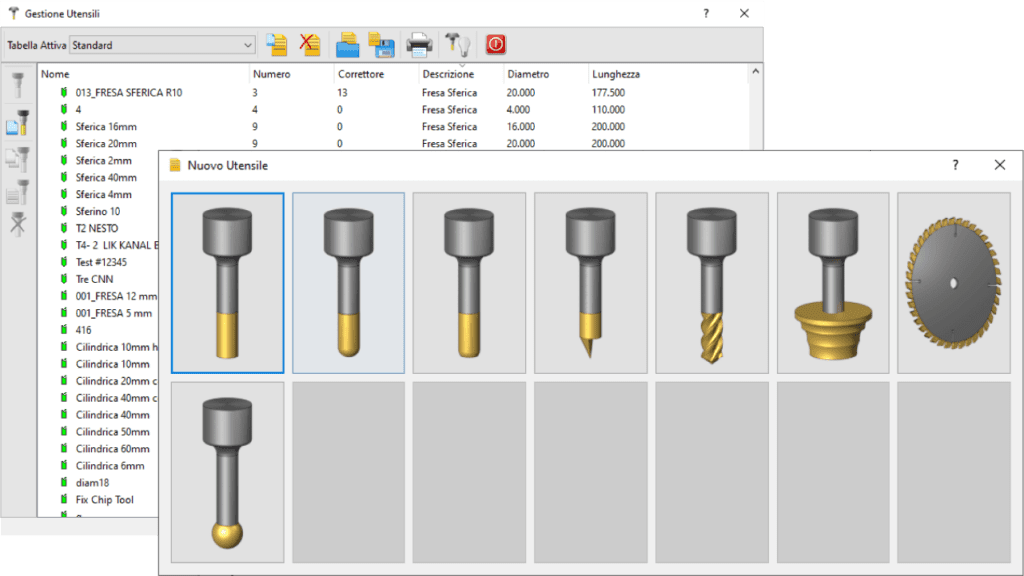

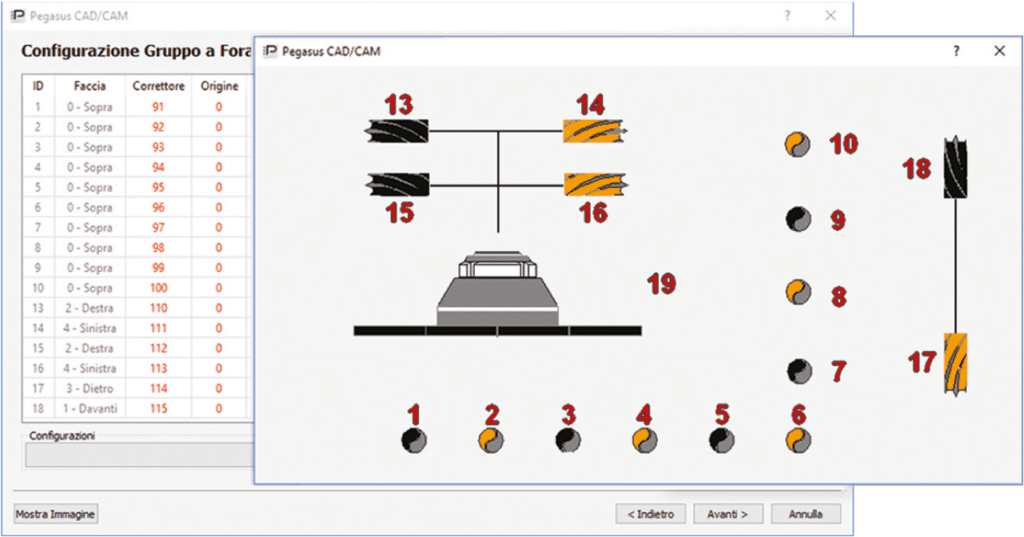

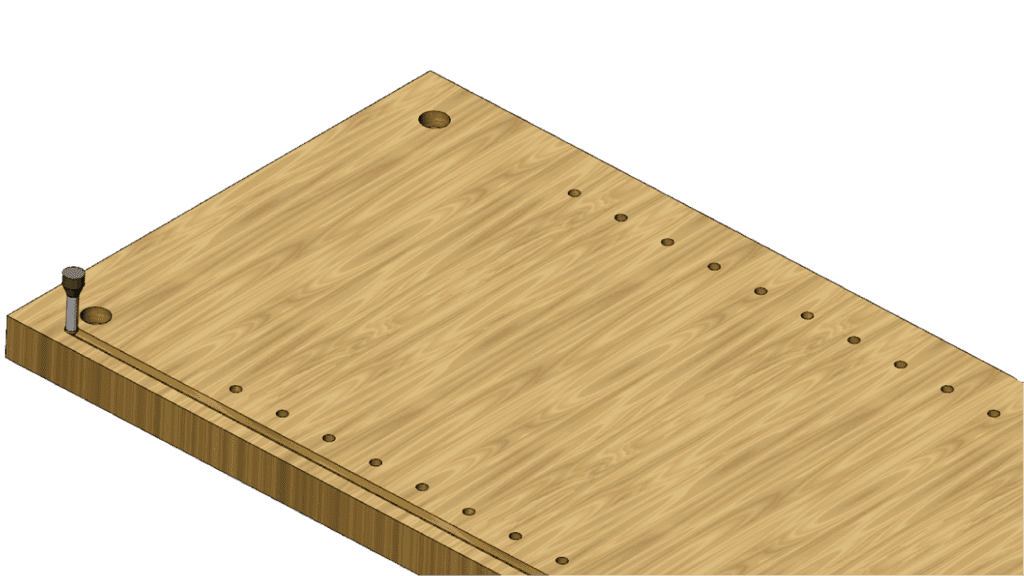

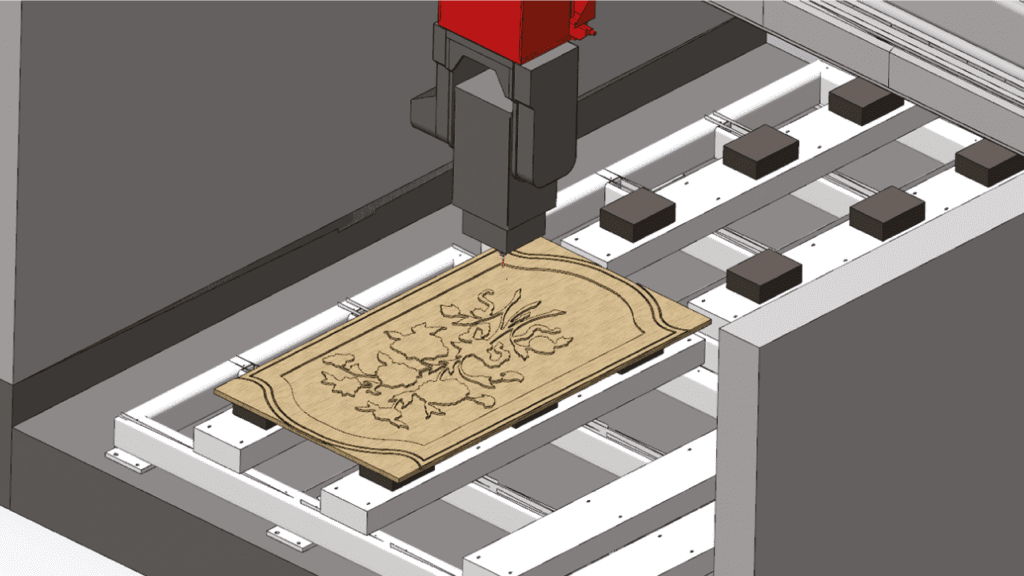

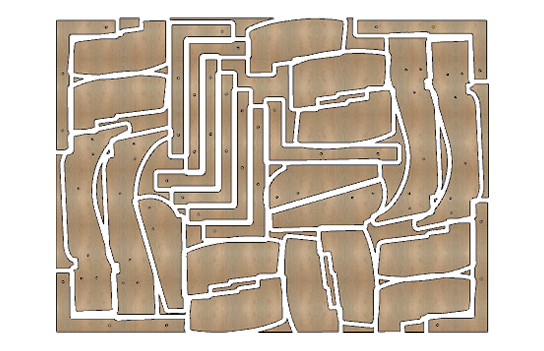

Software for woodworking with 3-axis pantographs up to the most complex 5-axis continuous machining centres.

![]() download the brochure

download the brochure

Stay informed, you'll always be one step ahead!

Subscribe to our Newsletter and receive the most important news and exclusive offers.